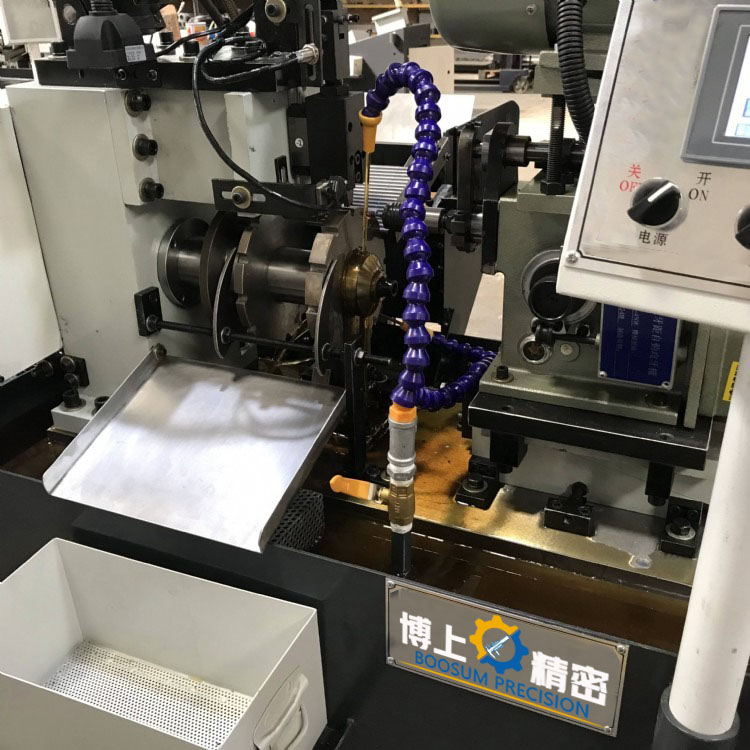

The long axis dedicated double headed automatic tapping machine is an efficient and precise automation equipment designed specifically for automatic tapping operations on hardware components such as shaft cores. It can quickly complete the machining processes such as tapping, threading, and threading of nuts, screws, and other components, greatly improving production efficiency and product quality.The working principle of this type of tapping machine is usually driven by a motor to rotate the spindle, while the tapping tool moves towards the surface of the workpiece under the drive of the feed mechanism. Under the action of cutting pressure, the tapping tool will cut the thread into the interior of the workpiece and rotate while applying pressure, making the cutting of the thread more precise. Once the predetermined depth is reached, the feed mechanism will stop moving, the drill bit will exit the workpiece, and then the tapping machine will drive the next round of cutting to continue the thread cutting work.

The long axis dedicated double head automatic tapping machine has high automation and intelligence characteristics, which can reduce manual operations, thereby saving costs and improving production efficiency. In addition, it also has the advantages of high precision, high stability, easy operation and maintenance, making it widely used in fields such as hardware processing and mechanical manufacturing.

It should be noted that although automatic tapping machines have many advantages, it is also necessary to strictly follow the operating procedures during use to ensure safe use of the equipment. Meanwhile, for workpieces of different materials and sizes, it is necessary to select appropriate tapping tools and machining parameters to ensure machining quality and efficiency.

Overall, the axis core automatic tapping machine is an efficient, precise, and easy to operate processing equipment, providing important technical support for industries such as hardware processing and mechanical manufacturing.

The equipment parameter table of the axis core automatic tapping machine may vary depending on different manufacturers and models, but generally speaking, the following are some common equipment

parameters:

| brand | BOOSUM PRECISION | inventory | - |

| working accuracy | 100% pass/stop gauge testing | Range of pitch for rolling screws | 1.5 |

| Dental Attack Ability | M2-M8 thread squeezing tap, M2-M10 cutting | automaticity | fully automatic |

| control form | PLC | Layout form | horizontal type |

| Lead Angle | 0.1mm | Main motor power | 1.5KW servo motor |

| Power Type | servo | type | tapping machine |

| Maximum spindle travel | 45mm | type model | BS-M02-08CS |

| product type | brand-new | after-sale service | Complete machine warranty for one year |

| Feeding method | Automatic feeding of hopper | Operation interface | HMI |

| Item number | 05 | Model selection | 08CS/16CS/32CS/1NC/2NC |

| function | Automatic feeding, hydraulic clamping, tap wear detection, blind hole alarm, no material alarm, infinitely variable speed, single/multi-stage feed, torque detection | Gama de velocidade do fuso | 0-1500 arbitrariamente ajustável |

Note que a tabela de parâmetros acima é apenas um exemplo e não os parâmetros reais de um modelo específico. Ao escolher uma máquina de roscagem automática de núcleos, recomenda-se consultar diretamente o fabricante ou consultar os manuais do produto relevante para obter as informações mais precisas sobre os parâmetros do equipamento.

Além disso, a seleção dos parâmetros do equipamento deve ser considerada de forma abrangente, com base nos requisitos específicos da aplicação, ambiente de produção, orçamento e outros fatores. Por exemplo, a gama de velocidades e a velocidade de avanço devem ser determinadas com base na dureza e nas especificações da rosca do material processado; a capacidade de roscagem e a potência do motor necessitam de considerar fatores como a eficiência de produção e a carga do equipamento.